BROWSE OUR LATEST PRODUCTS

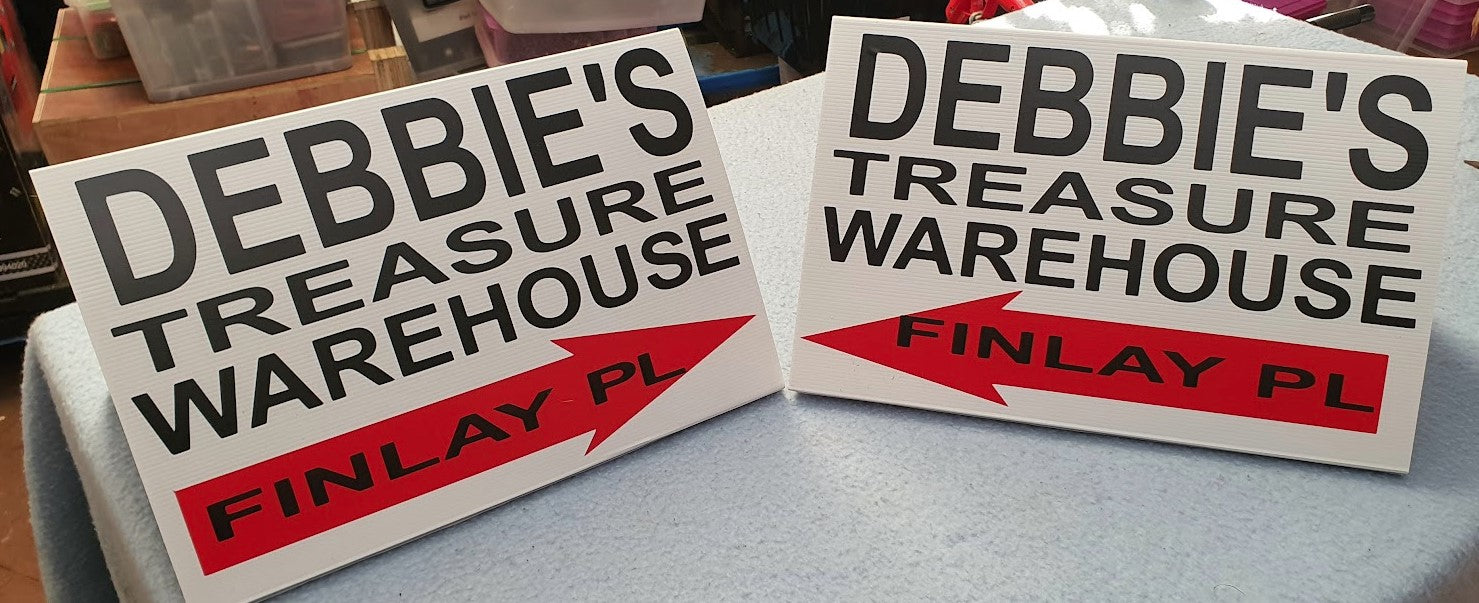

PT Innovations is a online business located in the Malaga area Established in 2012 We manufacture innovative new products and design using Australian made materials Signage ,House Signage , Auto decal , small run company stickers Home Maintenance, Steel cabinets , Fencing , Garden care and maintenance